The construction wood side uses imported wood sources, the texture is straight, and the material is uniform. From the source, it is ensured that unqualified wood will never flow into the processing link. The introduction of advanced band saws, multi-blade saws, polishing and drying ovens and other processing equipment, construction wood can be customized according to customer needs.

Wood is 100% degradable. If left untreated, it simply disintegrates into the soil and enriches it. Wood grows out of the soil, renews itself, and then returns to the earth, a completely natural process.

Wood is 100% degradable. If left untreated, it simply disintegrates into the soil and enriches it. Wood grows out of the soil, renews itself, and then returns to the earth, a completely natural process.

Wood reduces CO2 in the air, an inexhaustible forest resource provided by sustainable forestry. The production of wood produces very little waste. Waste from sawn timber production is often used to make pulp, particleboard or as fuel.

The components of the light wood structure plus fireproof gypsum wallboard can easily achieve the same fire performance as the masonry structure.It demonstrates the super performance level of light timber construction. Even building an economical timber-framed house has a fire resistance of no less than two hours.

The components of the light wood structure plus fireproof gypsum wallboard can easily achieve the same fire performance as the masonry structure.It demonstrates the super performance level of light timber construction. Even building an economical timber-framed house has a fire resistance of no less than two hours.

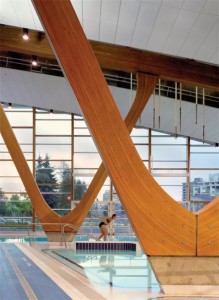

Compared with finished wood, glulam has high strength, the allowable bending stress can be increased by 50%, and the structure is uniform, the internal stress is small, and it is not easy to crack and warp; large-section glulam also has high fire resistance. In addition, the glulam does not have the problem of veneer cracks.