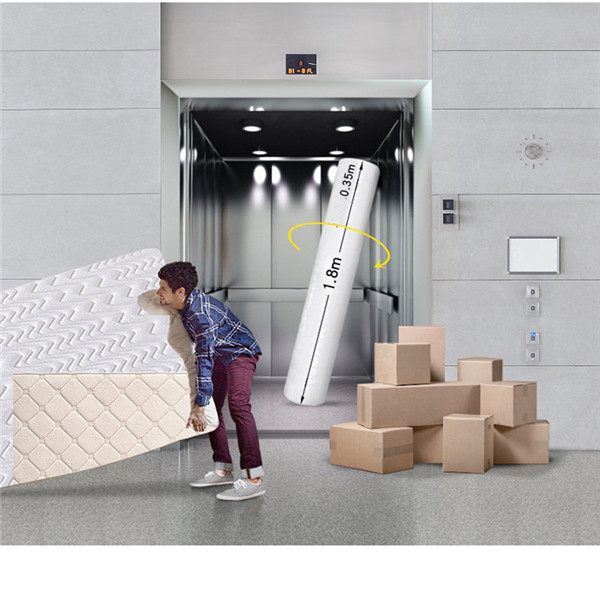

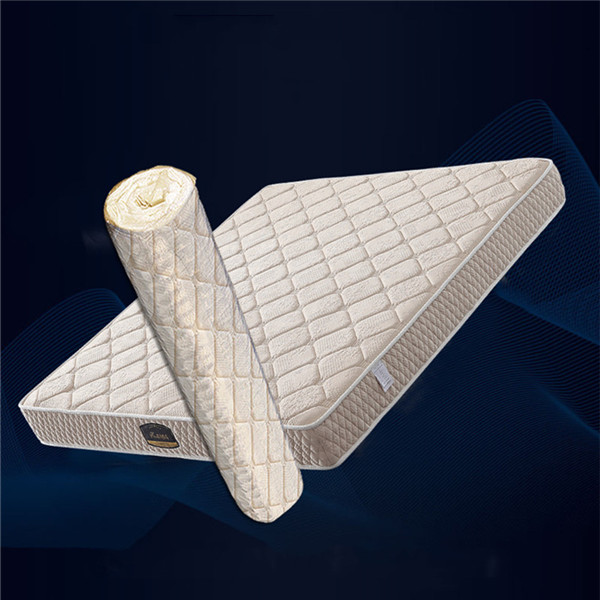

| Product Name | 1.8m 1.5m Convenient Compression Mattress Silent Independent Pocket Spring Roll Pack Mattress |

| Model | Amal-0418 |

| Thickness | 10inch /25cm |

| Top quilting cover | Double Knitting fabric quilted with 3cm foam and polyester fiber |

| Comfort layer | 2cm cooling gel memory 3cm support foam |

| Support system | eco-friendly white cotton pad 17cm pocket spring system with foam encased eco-friendly white cotton pad |

| Bottom cover | 1cm quilting cover |

| Color | Picture Color,or as your Request. |

| Size | Single,Double,Queen,King,customized |

| Type Of Shipping | Sea & Air & Express Shipping |

| Packing | Vacuum packed |

| MOQ | 10 PCS,more will be cheap. |

| Sample | Not Free,but accept customized design. |

| Time Of Delivery | 20-30 Days After Received The Deposit. |

| Port Of Shipment | Qingdao |

Our company is mainly engaged in the production and sales of furniture, sofas and mattresses. The company respects the enterprise spirit of "pragmatic, hard work, and responsibility", and creates a good corporate environment with integrity, win-win, and innovative business philosophy. It takes a brand-new management model, perfect technology, thoughtful service, and excellent quality as the basis for survival , We always insist on customer first and serve customers with heart, and insist on impressing customers with our own service.

Our company is mainly engaged in the production and sales of furniture, sofas and mattresses. The company respects the enterprise spirit of "pragmatic, hard work, and responsibility", and creates a good corporate environment with integrity, win-win, and innovative business philosophy. It takes a brand-new management model, perfect technology, thoughtful service, and excellent quality as the basis for survival , We always insist on customer first and serve customers with heart, and insist on impressing customers with our own service.

Sponge #mattresses are also a common type of mattress in daily life. This kind of sponge #mattresses are generally filled with sponges as mattress padding, and the made #mattresses are also called sponge #mattresses. Foam #mattresses are also called foam #mattresses. Ordinary foam #mattresses are generally made of polyurethane foam materials. Secondly, we must distinguish memory foam from foam #mattresses. Memory foam is just a type of foam mattress. Generally speaking, we call sponge. #Mattresses refer to ordinary foam #mattresses with only elasticity. There are two types of sponges, one is polyester sponge and the other is polyether sponge, these two kinds of sponges are similar in material. The performance and function are different. The former has strong tensile force, uniform pores and high density; the latter has low density and insufficient tensile force, and the appearance of pores is not as good as polyester. Most of the mattress padding is made of polyester sponge. Advantages of foam mattress: (1) Wide application range. Sponge #mattresses have higher resilience and higher compression load ratio. Some fire-resistant or flame-retardant sponges also have better flame resistance. They are widely used and can be used to make sofas, furniture sponge accessories, etc. . The cost of sponge #mattresses is cheap, and the price of sponge #mattresses on the market is around 2000. (2) Sponge #mattresses are soft and comfortable, and can perfectly fit the body shape of the human body. Compared with other mattress materials, it has the characteristics of lightness and comfort. At the same time, when sleeping with your partner, it will not be affected by frequent turning over. Partner sleep. (3) Sponge #mattresses have strong resilience and durability. When properly maintained, the #mattresses are not easy to deform, wear-resistant and durable.

Advantages of compressed packaging: 1. High barrier: The high barrier properties of different plastic materials are used to co-extrude the film to achieve high barrier effects on oxygen, water, carbon dioxide, and odor. 2. Stable performance: oil resistance, moisture resistance, low temperature freezing resistance, quality preservation, freshness preservation, odor preservation, and can be used for vacuum packaging, aseptic packaging, and inflatable packaging. 3. Low cost: Compared with glass packaging, aluminum foil packaging and other plastic packaging, co-extrusion film has a greater cost advantage to achieve the same barrier effect. Due to the simple process, the cost of the produced film products can be reduced by 10-20% compared with dry composite films and other composite films. 4. Flexible specifications: it can meet your different needs for different products.

Advantages of compressed packaging: 1. High barrier: The high barrier properties of different plastic materials are used to co-extrude the film to achieve high barrier effects on oxygen, water, carbon dioxide, and odor. 2. Stable performance: oil resistance, moisture resistance, low temperature freezing resistance, quality preservation, freshness preservation, odor preservation, and can be used for vacuum packaging, aseptic packaging, and inflatable packaging. 3. Low cost: Compared with glass packaging, aluminum foil packaging and other plastic packaging, co-extrusion film has a greater cost advantage to achieve the same barrier effect. Due to the simple process, the cost of the produced film products can be reduced by 10-20% compared with dry composite films and other composite films. 4. Flexible specifications: it can meet your different needs for different products.